We specialize in using non-crimp fibers to produce nonwoven fabrics, suitable for pure carbon fibers or glass fibers, or mixed with various thermoplastic fibers. We also handle different types of reinforcing fibers (like natural fibers, aramid fibers, decorative vapor-deposited fibers).

Pure Carbon Fiber Nonwoven Fabric:

- Made from 100% recycled waste carbon fibers

- Fiber lengths between 70mm-100mm

- FAW 100-250 g/m²

- Produced roll-to-roll with widths up to 1000mm

- Customizable based on customer product requirements (conductivity, flame retardancy, appearance variations)

Mechanical Property

Value

Max. Flexural Stress (MPa)

380

Flexural Modulus (GPa)

30

ILSS (Mpa)

50

Impact Strength (kg-cm/cm²)

10

*Test data with 50% epoxy resin content is for reference only. Actual data may vary slightly based on usage methods and objective conditions

Thermoplastic Carbon Fiber Nonwoven Fabric

- Made from 100% recycled waste carbon fibers

- Compatible with various plastic materials

(PP, PA6, PA66, PA11, PC, PET, PEEK, PPS, TPU, etc.) - FAW 200-350 g/m²

- Produced roll-to-roll with widths up to 1000mm

- Flexible ratio production (10-90%)

- Customizable based on customer product requirements (conductivity, flame retardancy, appearance variations)

TP/rCF = 50/50

Max. Flexural Stress (MPa)

Flexural Modulus (GPa)

Impact Strength (kg-cm/cm²)

Nylon6/rCF

347

23.4

8.63

Nylon66/rCF

402

26.6

6.58

PPS/rCF

368

31

5.67

PP/rCF

112

9.216

8.6

Natural Fiber Series - Flax & Jute

- Provides diverse solutions like dry yarn/prepreg/Plate

- Combined with resins like polypropylene (PP) or polylactic acid (PLA) for thermoplastic prepregs

- FAW 275-400 g/m²

- Suitable for vacuum infusion & molding & RTM

- Produced roll-to-roll with widths up to 72 inches (1800mm)

- Widely applied in automotive, yacht interiors, surfboards, luggage, etc.

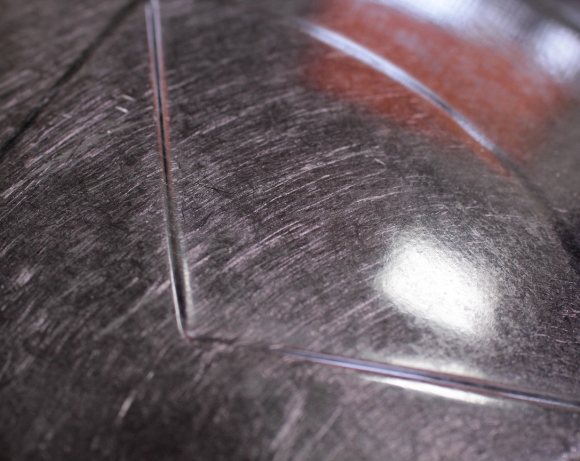

Thermoplastic Plate and molding development

- Compression molding or forming of thermoplastic carbon fiber felt

- Boards combined with UD or woven prepreg materials